Ok, first things first. What kind of motor are we trying to design. Well, for simplicity we are gonna be trying to duplicate the engine size of an estes rocket motor by its OD. (Outside Diameter) and length dimensions. The motor tube types we will be trying to duplicate will be C and D type motors which are standard size motors for most of the commercially avialable rocket models.

Lets get started, shall we? First, the parts list for this section of the project:

Parts List for the "Motor Tube Construction"

1. Yard Stick (Ruler will work, but will make things harder.)

2. Wood Glue (Elmers may work, but not as well.)

3. 1/2 Dowel

4. Plastic Packaging tape

5. Mixing Container (styrofoam cup is ideal)

6. Foam Brush

7. Plenty of rubber bands (just lots of them)

8. Scissors

9. Sandpaper

10. Counter that can be cleaned easily. (Im using a marble kitchen countertop, just something that wood glue wont permanently adhere too.

Now that we got the supplies, lets make the strips that will be later formed into the engine tubes. Precise Measuring and cutting will pay off later in the engine construction, trust me, you'll see why.

Okay, gonna do all of the rest of the project instructions in step by step format. (All pictures can be enlarged by clicking on them.

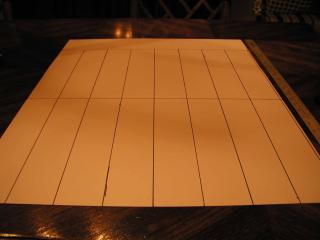

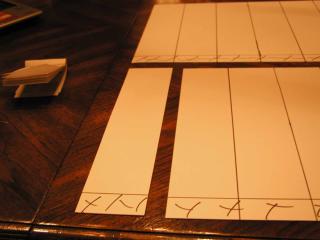

Step 1: Make sure you have the long side of the poster facing up and down and the shiny side facing down on the table. This will make motor tube installation into the model rocket slide in a little easier.

Step 2: Measure 24 inches up from the bottom on the left side of the posterboard and make a mark.

Step 3: Do the same thing on the right side as well.

Step 4: Draw a dark connecting line horizontally across connecting the two marks.

Step 5: Draw a line at the 12 inches up from the bottom, using the steps defined in #2-#4.

Step 6: Draw a mark every 2.75 inches on the bottom of the posterboard from left to right.

Step 7: Do the same on the top 24 inch line from left to right.

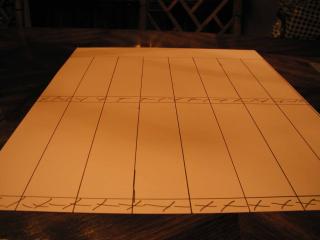

Step 8: Draw connecting lines vertically connecting each mark.

Step 9: Draw a line horizontally 1 inch from the bottom using the steps described earlier.

Step 10: Do the same thing but at 13 inches from the bottom.

Step 11: Cross our the area between the two close horizontal lines. (between 0 and 1 inch and 12 and 13 inch.)

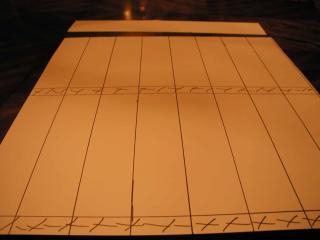

Step 12: Cut off the strip at the top.

Step 13: Cut the left over posterboard in half at the 12 inch line.

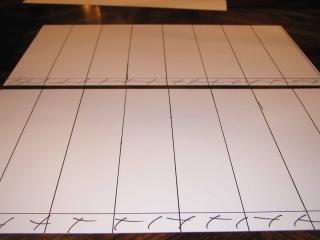

Step 14: Cut out each of the 2.75 inch wide strips down the vertical line.

Steph 15. Curl all of the cut out slips into a ball and hold together with a rubber band.

Note: Setting aside the curled and rubberbanded slips for a day or so, allow the slips to take a curled form when undone which makes forming the slips into tubes later much easier to do. This is however not a requirement, just makes it easier to roll into a tube later.Alright, we now have the slips, that we will now form into engine tubes.

Now we form these slips into engine tubes. Make sure whatever surface you are doing this on can clean up easily, cause wood glue has a bad/good habit (depends on the application) of adhering well to almost everything. The glue should be cleaned off the surface to provide a nice dry and clean surface for the following tubes every 3rd or 4th tube that you make. This makes curling alot easier too. Enough talk, not enough action, lets get onto forming these slip into something useful.

1. Cut your 1/2 inch hardwood dowel into a 9 inch long piece. (Why so long? I have found its alot easier to hand an oversized dowel than one just long enough for the tube itself.

2. Sand the dowel down till its nice and smooth. This will allow the tape that we will stick on the dowel in the next step to adhere more readily.

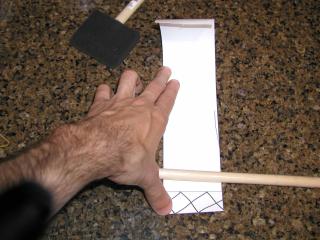

3. Apply a piece of clear packaging tape down the length of the dowel. Now wrap the piece around the dowel and overlap the remaining end of the tape over itself. Make sure you leave no creases or air bubbles, if so startover with a new peice. Why does it need to be so perfect? Because the dowel and whatever is attached to it, will be the mold persay that will reflect itself on the inside of the motor tube later on.

4. Take a slip and start at the crossed out section facing up and beging curling onto the dowel till its completely curled, rubber band the tube tight with two rubber bands, one on each end of the tube and set aside. What we just did was called "pre-curling". This makes the final curling when it is glued alot easier to do. It also lowers the chances that their will be a flow in final tube construction which could lead to an engine failure.

5. Repeat step #4 until all your slips are pre-curled and rubber banded.

6. Take your mixing container (in my case i use a styrofoam cup, which can be cut in half to make mixing and brushing more easy and rediablly accessible.) and fill it with a 1:1 ratio of glue to water. This should create a slurry type mixture that is not watered down, or too thick to brush on to posterboard slips.

7. Now take your first slip that you pre-curled and take off the rubber bands and set them to the side in easy reach to replace on the tube after glued.

8. Now take your brush and slather on a moderate layer of glue/water slurry just above the crossed out section and to the other end. DO NOT PUT GLUE ON THE CROSSED OUT SECTION. This is because we want to be able to get the tube off of the dowel with out ruining the tube itself.

9. Wait about 5-10 seconds just until the posterbard begins to suck in the glue, and apply a thinner layer of the glue/water slurry.

10. Now curl the pre-glue slathered slip on the dowel, starting with the crossed-out-non-glued section frist facing into th dowel. Make sure to keep the slip straight, if it ges off any, use a tool to straighten it or back up and start over from the point it started going off center.

11. Once curled all the way, re-rubberband the tube and slide it off the dowel.

12. Take the motor tube and paint glue on both ends of the rocket to seal the ends.

13. Slide a small drop down the inside of the tube to seal the area where the crossed-end of the slip touches the curled tube to seal that area too.

14. Repeat steps #10-#13 until all the slips are glued and rubberbanded and allow to dry overnight.

Btw, if anyone can tell me whats wrong with this picture of completed tubes, than you will win a round of applause from me. What? Did you actually think I had a worthwhile prize?Alright, we now have the motor tubes. Be sure to save one of the tubes for "Molding The Fuel" section. The next step is to make the nozzles:

Section 2: Making The Nozzles